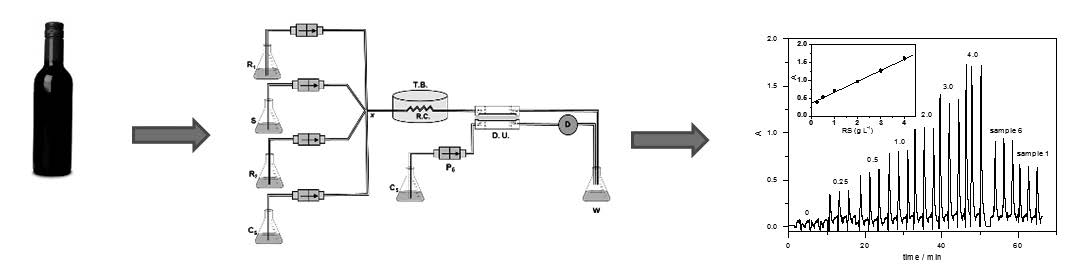

SPECTROPHOTOMETRIC DETERMINATION OF REDUCING SUGAR IN WINES EMPLOYING IN-LINE DIALYSIS AND A MULTICOMMUTED FLOW ANALYSIS APPROACH

- Dialysis,

- Flow injection analysis,

- Multicommutation,

- Reducing sugar,

- Wine

Copyright (c) 2018 Journal of the Chilean Chemical Society

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.

Abstract

A multicommuted flow procedure for the spectrophotometric determination of reducing sugars in wine has been developed. A dialysis unit was incorporated in the system to minimize matrix interferences and eliminate the colored compounds of the wine. The oxidation-reduction reaction in an alkaline medium between reducing sugars and the Cu2+-Neocuproine complex was employed. The compound formed was monitored at 460 nm. In the proposed procedure, there was a linear response between 0.25 and 4.0 g L-1 reducing sugars (y = (0.36 ± 0.02) + (0.31 ± 0.01) * x, R = 0.9975, n = 6), a coefficient of variance of 2.6% for a reducing sugar solution of 2.0 g L-1 (n = 7), a limit of detection estimated at 0.03 g L-1, reagent consumption per determination of 0.330, 0.128 and 0.160 mg for neocuproine, CuSO4 and NaOH, respectively. A sampling throughput of 45 determinations per hour was achieved. The proposed system was applied to wine samples and comparing the results with an AOAC official method no significant difference at a 95% confidence level.

References

- A.L. Galant, R.C. Kaufman, J.D. Wilson, Food Chem., 188, 149, (2015).

- J. Clayden, N. Greeves, S. Warren, P. Wothers, Organic Chemistry. Oxfor University Press, N.Y., 2001, pp.15-42.

- R.B. Boulton, V.L. Singleton, L.F. Bisson, R.E. Kunkee, Principles and practices of winemaking. Chapman & Hall, N. Y., 1996, 585 p.

- OIV. Compendium of International Methods of Analysis of Wines and Musts. International Organisation of Vine and Wine, Paris, 2014, 504 p.

- K.S. Başkan, E. Tütem, E. Akyüz, S. Özen, R. Apak, Talanta, 147, 162, (2016).

- P. González, M. Knochen, M.K. Sasaki, E.A.G. Zagatto, Talanta, 143, 419, (2015).

- C.I.C. Silvestre, J.L.M. Santos, J.L.F.C. Lima, E.A.G. Zagatto, Anal. Chim. Acta, 652(1-2), 54, (2009).

- A.D. Batista, R.S. Amais, F.R.P. Rocha, Microchem. J., 124, 55, (2016).

- P.A.B. da Silva, G.C.S. de Souza, D.M.D.S. Leotério, M. F. Belian, W. E. Silva, A.P.S. Paim, A.F. Lavorante, J. Food Compos. Anal., 40, 177, (2015).

- L.G. Decnop-Weever, J.C. Kraak, Anal. Chim. Acta., 337(2), 125, (1997).

- M. Naghizadeh, M.A. Taher, M. Behzadi, F.M. Hassani, Chem. Eng. J., 281, 444, (2015).

- A.C. Pereira, F.R.P. Rocha, Anal. Methods, 5(8), 2104, (2013).

- A.C. Pereira, B.F. Reis, F.R.P. Rocha, Talanta, 131, 21, (2015).

- A.N. Ramdzan, P.J. Mornane, M.J. McCullough, W. Mazurek, S.D. Kolev, Anal. Chim. Acta, 786, 70, (2013).

- M.C. Yebra, M. Gallego, M. Valcárcel, Anal. Chim. Acta, 276(2), 385, (1993).

- M.D. Luque de Castro, J.L. Luque-Garcia, Anal. Letters, 33(6), 963, (2000).

- A.N. Araújo, J.L.F.C. Lima, A.O.S.S. Rangel, M.A. Segundo, Talanta, 52(1), 59, (2000).

- M.A. Feres, P.R. Fortes, E.A.G. Zagatto, J.L.M. Santos, J.L.F.C. Lima, Anal. Chim. Acta, 618(1), 1, (2008).

- G.C.S. de Souza, P.A. Bezerra da Silva, D.M.S. Leotério, A.P.S. Paim, A.F. Lavorante, Food Control, 46, 127, (2014).

- J.C.Miranda, M.Y. Kamogawa, B.F. Reis, Sens. Actuators B Chem., 207, 811, (2015).

- D.S.M. Ribeiro, C. Frigerio, J.L.M. Santos, J.A.V. Prior, Anal. Chim. Acta, 735, 69, (2012).

- D.L.Rocha, F.R.P. Rocha, Inter. Environ. Anal. Chem., 93(13), 1389, (2013).

- W.R. Melchert, B.F. Reis, F.R.P. Rocha, Anal. Chim. Acta, 714, 8, (2012).

- A.C. Pereira, F.R.P. Rocha, Anal. Chim. Acta, 829, 28, (2014).

- A.L.D.Comitre, B.F. Reis, Anal. Chim. Acta, 479(2), 185, (2003).

- A.L.D.Comitre, B.F. Reis, Talanta, 65(4), 846, (2005).

- L. Li, L. Fang, Y. He, Instr. Sci. Technol., 31(3), 269, (2003).

- M.A. Sanchez, F.R.P. Rocha, Anal. Chim. Acta, 694(1-2), 95, (2011).

- S.M. Oliveira, T.I.M.S. Lopes, I.V. Tóth, A.O.S.S. Rangel, Talanta, 81(4- 5), 1735, (2010).

- S.M. Oliveira, T.I.M.S. Lopes, I.V. Tóth, A.O.S.S. Rangel, J. Agric. Food Chem., 57(9), 3415, (2009).

- C.A. Tumang, M.C. Tomazzini, B.F. Reis, Anal. Sci., 19(12), 1683, (2003).

- D.M.S. Leotério, P.A.B. Silva, G.C.S. Souza, A.D.A. Alves, M.F. Belian, A. Galembeck, A.F. Lavorante, Food Control, 57, 225, (2015).

- G.W. Latimer Jr, The Official Methods of Analysis of AOAC International, 19th Edition. Rockville, USA, 2012.

- F.P. Miller, F. Agnes, J.M. Vandome, J. McBrewster, Fick’s Law of Diffusion. VDM Publishing, Saarbrücken, 2009, 82p.

- J. Pawliszyn, Comprehensive Sampling and Sample Preparation: Analytical Techniques for Scientists. Academic Press, N.Y., 2012, 3200p.

- G. Lee, M.V. Rossi, N. Coichev, H.D. Moya, Food Chem., 126(2), 679, (2011).

- R. Ravichandran, M. Rajendran, D. Devapiriam, Food Chem. 146, 472, (2014).

- A. Maquieira, M.D. Luque de Castro, M. Valcarcel, Analyst, 112(11), 1569, (1987).