ENHANCED ELECTROACTIVE ARTIFICIAL MUSCLE USING CNFS/IONIC LIQUID IN A PVDF(HFP) POLYMER GEL: A LOW-COST ALTERNATIVE TO CNT-BASED ACTUATORS

- Electroactive Artificial Muscle,

- Electrochemical Actuator,

- Carbon Nanofiber,

- Ionic Liquid,

- PVdF(HFP)

- Electroactive Polymers ...More

Copyright (c) 2025 SChQ

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.

Abstract

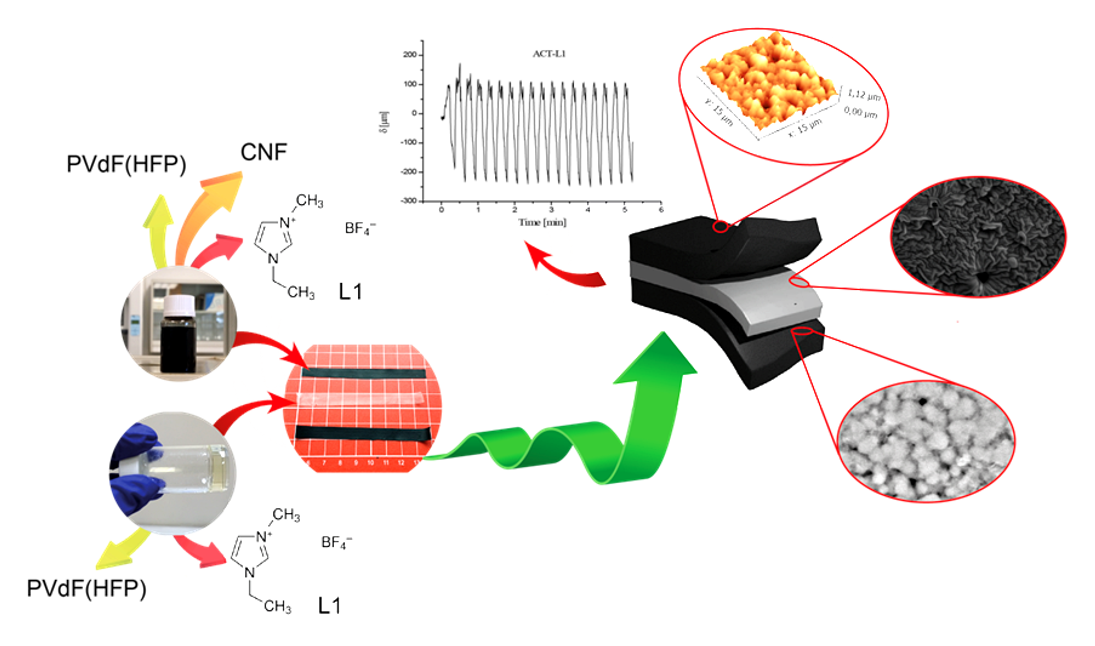

This study presents the development and characterization of two electroactive actuators, ACT-L1 and ACT-L2, based on carbon nanofibers (CNFs) and two different ionic liquids: EMIBF4 (L1) and EMIN[(CN)2] (L2). The actuators were designed in a three-layer configuration and characterized using SEM, AFM, FT-IR, IEC, and Young’s modulus analysis.

SEM and AFM images revealed that electrode layers with L2 exhibited spherical grains and increased roughness, while FT-IR confirmed modifications in the polymer’s crystalline structure due to CNFs and ionic liquid incorporation. The electrolyte films exhibited similar chemical and mechanical properties regardless of the ionic liquid used, except for roughness.

Performance evaluation demonstrated that both actuators showed stable and reproducible movement under a ±2.0 V voltage window. However, ACT-L1 achieved a maximum displacement of 400 µm, significantly outperforming ACT-L2 (17 µm), likely due to morphological differences in the electrolyte surface. The strain generated by ACT-L1 under ±2.0 V and 0.1 Hz was comparable to previously reported multiwalled carbon nanotube (MWCNT) actuators.

These results suggest that CNF-based actuators offer a promising and cost-effective alternative to CNT-based artificial muscles for applications in robotics, biomedical devices, and other fields.

References

- Vohrer, U.; Kolaric, I.; Haque, M. H.; Roth, S.; (Sobhan Sharafkhani, 2021) Detlaff-Weglikowska, U. Carbon N. Y, 2004, 42, 1159–1164, doi:10.1016/j.carbon.2003.12.044.

- Mahanty, B.; Maity, K.; Sarkar, S.; Mandal, D. Mater. Today Proc. 2020, 21, 1964–1968, doi:10.1016/j.matpr.2020.01.282.

- Fraysse, J.; Minett, A. I.; Jaschinski, O.; Duesberg, G. S.; Roth, S. Carbon N. Y. 2002, 40, 1735–1739, doi:10.1016/S0008-6223(02)00041-6.

- Kwon, K. S.; Ng, T. N. Org. Electron. physics, Mater. Appl. 2014, 15, 294–298, doi:10.1016/j.orgel.2013.11.026.

- Lee, B. K.; Park, S. J.; Kim, D. S. Curr. Appl. Phys. 2013, 13, 1520–1524, doi:10.1016/j.cap.2013.05.011.

- Prasad, B.; Gill, F. S.; Panwar, V.; Anoop, G. Compos. Part B Eng. 2019, 173, 106990, doi:10.1016/j.compositesb.2019.106990.

- Park C-L.; Goh B.; Kim E.; Choi J.; Kim S., Carbon, Volume 220, 20 February 2024, 118775, https://doi.org/10.1016/j.carbon.2023.118775

- Terasawa, N.; Ono, N.; Mukai, K.; Koga, T.; Higashi, N.; Asaka, K. Carbon N. Y. 2012, 50, 311–320, doi:10.1016/j.carbon.2011.08.072.

- Chen, I.-W. P.; Cottinet, P.-J.; Tsai, S.-Y.; Foster, B.; Liang, R.; Wang, B.; Zhang, C. Sensors Actuators B Chem. 2012, 171–172, 515–521, doi:10.1016/j.snb.2012.05.022.

- Takeuchi, I.; Asaka, K.; Kiyohara, K.; Sugino, T.; Terasawa, N.; Mukai, K.; Fukushima, T.; Aida, T. Electrochim. Acta, 2009, 54, 1762–1768, doi:10.1016/j.electacta.2008.10.007.

- Biso, M.; Ansaldo, A.; Picardo, E.; Ricci, D. Carbon N. Y., 2012, 50, 4506–4511, doi:10.1016/j.carbon.2012.05.032.

- Terasawa, N.; Takeuchi, I.; Matsumoto, H. Sensors Actuators, B Chem. 2009, 139, 624–630, doi:10.1016/j.snb.2009.03.057.

- Mukai, K.; Asaka, K.; Kiyohara, K.; Sugino, T.; Takeuchi, I.; Fukushima, T.; Aida, T. Electrochim. Acta, 2008, 53, 5555–5562, doi:10.1016/j.electacta.2008.02.113.

- Sugino, T.; Kiyohara, K.; Takeuchi, I.; Mukai, K.; Asaka, K. Sensors Actuators, B Chem. 2009, 141, 179–186, doi:10.1016/j.snb.2009.06.002.

- Sobhan Sharafkhani, M, K 2021, 10 (9060).

- Terasawa, N.; Takeuchi, I. Electrochim. Acta, 2014, 123, 340–345, doi:10.1016/j.electacta.2013.12.156.

- Jung, J. H.; Vadahanambi, S.; Oh, I. K. Compos. Sci. Technol, 2010, 70, 584–592, doi:10.1016/j.compscitech.2009.12.007.

- Jung, J. H.; Jeon, J. H.; Sridhar, V.; Oh, I. K. Carbon N. Y. 2011, 49, 1279–1289, doi:10.1016/j.carbon, 2010, 11.047.

- Łuczak, J.; Hupka, J.; Thöming, J.; Jungnickel, C. Colloids Surfaces A Physicochem. Eng. Asp. 2008, 329, 125–133, doi:10.1016/j.colsurfa.2008.07.012.

- Shiddiky, M. J. A.; Torriero, A. A. J. Biosens. Bioelectron. 2011, 26, 1775–1787, doi:10.1016/j.bios.2010.08.064.

- Yuan, C.; Su, L.; Yang, K.; Li, Z.; Cheng, X.; Wang, Y.; Li, L. Colloid Polym. Sci. 2015, 293, 925–932, doi:10.1007/s00396-014-3466-7.

- Wu, Y. S.; Yang, C. C.; Luo, S. P.; Chen, Y. L.; Wei, C. N.; Lue, S. J. Int. J. Hydrogen Energy 2017, 42, 6862–6875, doi:10.1016/j.ijhydene.2016.11.201.

- Daneshkhah, A.; Shrestha, S.; Agarwal, M.; Varahramyan, K. Sensors Actuators, B Chem. 2015, 221, 635–643, doi:10.1016/j.snb.2015.06.145.

- Kabir, E.; Khatun, M.; Nasrin, L.; Raihan, M. J.; Rahman, M. J. Phys. D. Appl. Phys., doi:10.1088/1361-6463/aa5f85.

- Gong W.; Yang W.; Fu F.; Nano Energy 2024, 131, 110277.

- Wu, C. G.; Lu, M. I.; Chuang, H. J. Polymer (Guildf). 2005, 46, 5929–5938, doi:10.1016/j.polymer.2005.05.077.

- Wang, J.; Zheng, L.; Wu, Z.; Zhang, Y.; Zhang, X. J. Memb. Sci. 2016, 497, 183–193, doi:10.1016/j.memsci.2015.09.024.

- Sil, A.; Sharma, R.; Ray, S. Surf. Coatings Technol. 2015, 271, 201–206, doi:10.1016/j.surfcoat.2014.12.036.

- Minett, A.; Fràysse, J.; Gang, G.; Kim, G.-T.; Roth, S. Curr. Appl. Phys. 2002, 2, 61–64, doi:10.1016/S1567-1739(01)00100-6.

- Canning, J.; Bandyopadhyay, S.; Biswas, P.; Aslund, M. World’s largest Science, Technology & Medicine Open Access book publisher., doi:10.5772/50570.

- Spasova, M.; Manolova, N.; Markova, N.; Rashkov, I. Appl. Surf. Sci. 2016, 363, 363–371, doi:10.1016/j.apsusc.2015.12.049.

- Soroush Soltani, N. K. 2022, 12, 6111.

- Huang, H.; Chen, B.; Wu, J.; Wang, Y.; Shen, Z.; Li, L.; Wang, Y.; Wang, Y.; Li, X. Mater. Today Commun. 2022, 103052, https://doi.org/10.1016/j.mtcomm.2021.103052.

- Keshavarz, S.; Okoro, O.; Hamidi, M. Coord. Chem. Rev. 2022, 472, 214770, https://doi.org/10.1016/j.ccr.2022.214770.

- Zhao, Z.; Zheng, W.; Yu, W.; Long, B. Carbon N. Y. 2009, 47, 2118–2120, doi:10.1016/j.carbon.2009.03.043.

- Jin, Z.; Pramoda, K. P.; Goh, S. H.; Xu, G. Compos. Mater. Res. Bull. 2002, 37, 271–278, doi:10.1016/S0025-5408(01)00775-9.

- Zhang, S.; Kumar, S. Macromol. Rapid Commun. 2008, 29, 557–561.

- Saikia, D.; Kumar, A. I. Electrochim. Acta 2004, 49, 2581–2589, doi:10.1016/j.electacta.2004.01.029.

- Terasawa, N.; Ono, N.; Hayakawa, Y.; Mukai, K.; Koga, T.; Higashi, N.; Asaka, K. Sensors Actuators, B Chem. 2011, 160, 161–167, doi:10.1016/j.snb.2011.07.027.

- Terasawa, N.; Ono, N.; Mukai, K.; Koga, T.; Higashi, N.; Asaka, K. Sensors Actuators, B Chem. 2012, 163, 20–28, doi:10.1016/j.snb.2011.11.065.

- Terasawa, N.; Asaka, K. RSC Adv. 2016, 6, 66360–66367, doi:10.1039/C6RA08676D.