- Biodegradability,

- mustard oil,

- nanoindentation,

- micro-chipping,

- micro-softening

- lubricating properties ...More

Copyright (c) 2021 SChQ

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.

Abstract

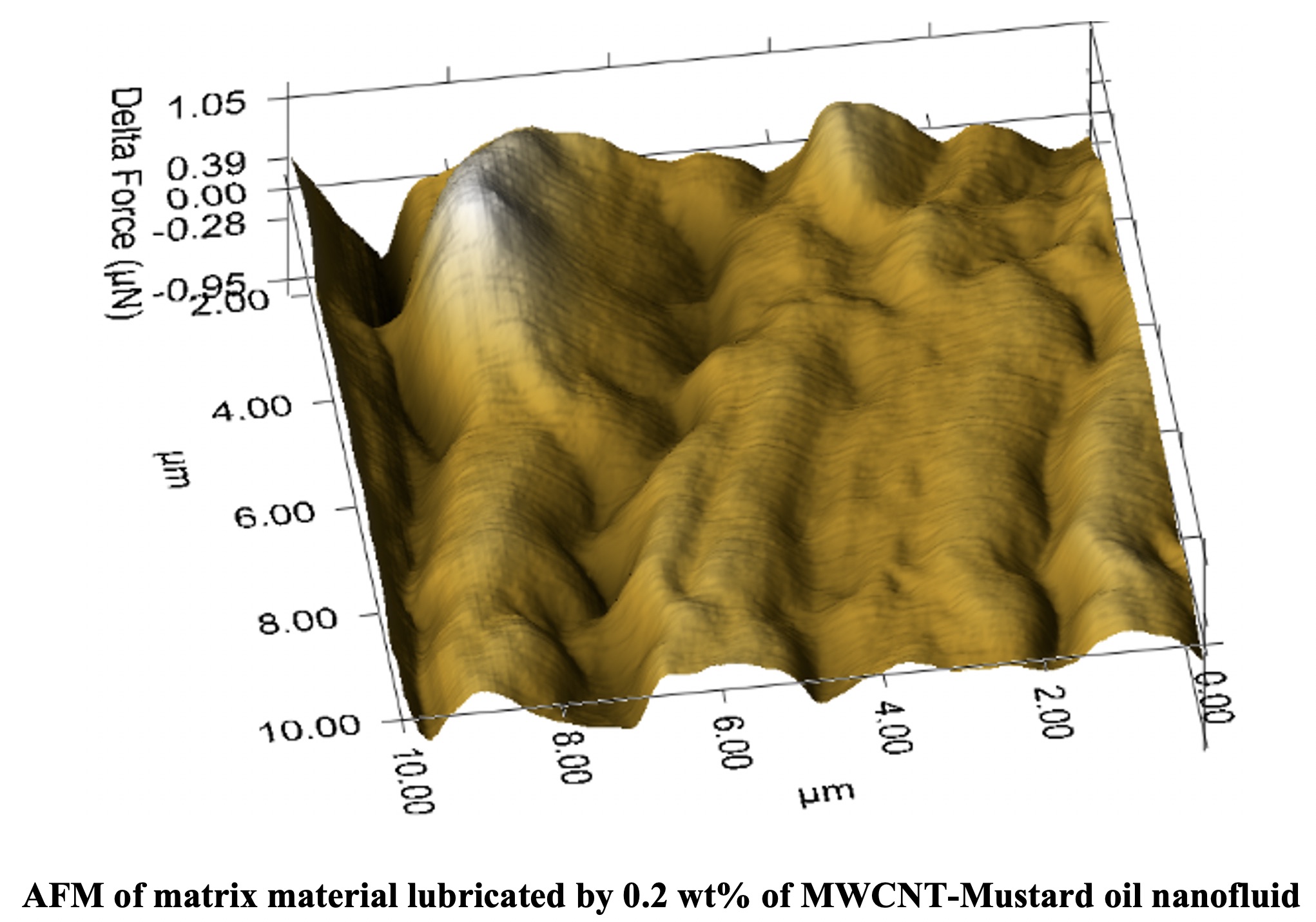

Nowadays, environmentally friendly lubricants are developed to meet the standards of biodegradability, toxicity, and bioaccumulation potential that reduce the adverse consequences to the aquatic atmosphere compared to conventional mineral based lubricants. In this study, an attempt made to enhance the feasibility of utilizing the Mustard oil as a commercial lubricating agent by homogeneously dispersing MWCNTs as an additive. The average crystallite size, surface morphology, and elements of MWCNT are characterized through XRD, SEM, EDS, and FTIR techniques, respectively. The surface deformation rate of matrix material (Mg) lubricated by Mustard oil and different weight fractions of MWCNT-Mustard oil nanofluid are estimated through the Nanoindentation technique. The hardness, Young's modulus, and AFM topography of the interacting surface infer that the dispersed MWCNT significantly enhance the lubricating properties of Mustard oil through micro-chipping and micro-softening effect.

Nowadays, environmentally friendly lubricants are developed to meet the standards of biodegradability, toxicity, and bioaccumulation potential that reduce the adverse consequences to the aquatic atmosphere compared to conventional mineral based lubricants. In this study, an attempt made to enhance the feasibility of utilizing the Mustard oil as a commercial lubricating agent by homogeneously dispersing MWCNTs as an additive. The average crystallite size, surface morphology, and elements of MWCNT are characterized through XRD, SEM, EDS, and FTIR techniques, respectively. The surface deformation rate of matrix material (Mg) lubricated by Mustard oil and different weight fractions of MWCNT-Mustard oil nanofluid are estimated through the Nanoindentation technique. The hardness, Young's modulus, and AFM topography of the interacting surface infer that the dispersed MWCNT significantly enhance the lubricating properties of Mustard oil through micro-chipping and micro-softening effect.

References

2. Y. Singh, A. Farooq, A. Raza, M.A. Mahmood, S. Jain, Sustainability of a non-edible vegetable oil based bio-lubricant for automotive applications: A review, Process Saf. Environ .111 (2017) 701-713.

3. J.F. Hoffmann, J.F. Henry, G. Vaitilingom, R. Olives, M. Chirtoc, D. Caron, Temperature dependence of thermal conductivity of vegetable oils for use in concentrated solar power plants, measured by 3omega hot wire method, Int. J. Therm. Sci. 107 (2016) 105-110.

4. M. Ghasemlou, F. Daver, E. P. Ivanova, B. Adhikari, Polyurethanes from seed oil-based polyols: A review of synthesis, mechanical and thermal properties, Ind. Crops Prod. 142 (2019) 111841.

5. Y. Wang, C. Li, Y. Zhang, B. Li, M. Yang, X. Zhang, Comparative evaluation of the lubricating properties of vegetable-oil-based nanofluids between frictional test and grinding experiment, J. Manuf. Proc. 26 (2017) 94-104.

6. S.V. Sujith, A.K. Solanki, R.S. Mulik, Experimental evaluation on rheological behavior of Al2O3-pure coconut oil nanofluids, J. Mol. Liq. 286 (2019) 110905.

7. S.B. Mousavi, S.Z. Heris, M.G. Hosseini, Experimental investigation of MoS2/diesel oil nanofluid thermophysical and rheological properties, Int. Commun. Heat Mass. 108 (2019) 104298.

8. S.R. Valantina, K.A. Jayalatha, D.R.P. Angeline, S. Uma, B. Ashvanthe, Synthesis and characterisation of electro-rheological property of novel eco-friendly rice bran oil and nanofluid, J. Mol. Liq. 256 (2018) 256-66.

9. K.M. Kumar, A. Ghosh, Assessment of cooling-lubrication and wettability characteristics of nano-engineered sunflower oil as cutting fluid and its impact on SQCL grinding performance, J. Mater. Process. Tech. 237 (2016) 55-64.

10. S.S. Sanukrishna, S. Vishn, T.S. Prakash, Effect of oxide nanoparticles on the thermal, rheological and tribological behaviours of refrigerant compressor oil: An experimental investigation, Int. J. Refrig. 90 (2017) 32-45.

11. S.U. Ilyas, M. Narahari, J.T.Y, Thenga, R. Pendyala, Experimental evaluation of dispersion behavior, rheology and thermal analysis of functionalized zinc oxide-paraffin oil nanofluids, J. Mol. Liq. 294 (2019) 111613.

12. Y. Mohammadfam, S.Z. Heris, L. Khazini Experimental Investigation of Fe3O4/hydraulic oil magnetic nanofluids rheological properties and performance in the presence of magnetic field, Tribol. Int. 142 (2020) 105995.

13. V. Zin, F. Agresti, S. Barison, L. Litti, L. Fedele, M. Meneghetti, M. Fabrizio Effect of external magnetic field on tribological properties of goethite (a-FeOOH) based nanofluids, Tribol. Int. 127 (2018) 341-50.

14. X. Liu, N. Xu, W. Li, M. Zhang, L. Chen, W. Lou, X. Wang, Exploring the effect of nanoparticle size on the tribological properties of SiO2/polyalkylene glycol nanofluid under different lubrication conditions, Tribol. Int. 109 (2017) 467-72.

15. A.K. Sharma, A.K. Tiwari, A.R. Dixita, Characterization of TiO2, Al2O3 and SiO2 Nanoparticle based Cutting Fluids, Mat. Today Proceed. 3(6) (2016) 1890-1898.

16. S.M. Hashemi, M.A.A. Behabadi, An empirical study on heat transfer and pressure drop characteristics of CuO–base oil nanofluid flow in a horizontal helically coiled tube under constant heat flux, Int. Commun. Heat Mass. 39(1) (2012) 144-151.

17. M.J. Babu, N. Sandeep, Effect of nonlinear thermal radiation on non-aligned bio-convective stagnation point flow of a magnetic-nanofluid over a stretching sheet, Alexandria Eng. J. 55(3) (2016) 1931-1939.

18. M. Anish, J. Jayaprabakar, V. Jayaprakash, A. Prabhu, V.B. Ram, M.A. Jijo, Measurement dependent temperature of thermal conductivity and viscosity by using Al2O3- Therminol 55 based nanofluid, Mat. Today Proceed. DOI: 10.1016/j.matpr.2019.05.457.

19. M. Hatami, S.M. Rezaei, M. Tahari, D. Jing, Recent developments in magneto-hydrodynamic Fe3O4 nanofluids for different molecular applications: A review study, J. Mol. Liq. 250 (2018) 244-258.

20. N.N. Esfahani, D. Toghraie, M. Afrand, A new correlation for predicting the thermal conductivity of ZnO–Ag (50%–50%)/water hybrid nanofluid: An experimental study, Powder Technol. 323 (2018) 367-73.

21. B.A.J. Rose, H. Singh, N. Verma, S. Tassou, S. Suresh, N. Anantharaman, Investigations into nanofluids as direct solar radiation collectors, Solar Energy 147 (2017) 426-31.

22. S. Akilu, A.T. Baheta, A.A. Minea, K.V. Sharma, Rheology and thermal conductivity of non-porous silica (SiO2) in viscous glycerol and ethylene glycol based nanofluids, , Int. Commun. Heat Mass. 88 (2017) 245-53.

23. M.F. Nabil, W.H. Azmia, K.A. Hamid, R. Mamat, Experimental investigation of heat transfer and friction factor of TiO2-SiO2 nanofluids in water:ethylene glycol mixture, Int. J. Heat Mass Transf. 12 (2018) 1361-1369

24. N. Yadav, A.K. Jaiswal, K.K. Dey, V.B. Yadav, G. Nath, A.K. Srivastava, R. R. Yadava, Trimetallic Au/Pt/Ag based nanofluid for enhanced antibacterial response, Mat. Chem. Phy. 218 (2018) 10-17.

25. S.S. Chaudhari, R.R. Chakule, P.S. Talmale, Experimental Study of Heat Transfer Characteristics of Al2O3 and CuO Nanofluids for Machining Application, Mat. Today Proceed. 18(3) (2019) 788-797.

26. L.T. Benos, E.G. Karvelas, I.E. Sarris, Crucial effect of aggregations in CNT-water nanofluid magnetohydrodynamic natural convection, Therm. Sci. Eng. Progress 11 (2019) 263-271.

27. M.S.B. Reddy, N. Jayarambabu, R.K.K. Reddy, S. Kailasa, K.V. Rao, Study of acoustic and thermodynamic factors of synthesized ZnO-water nanofluid by ultrasonic technique, Mat. Today Proceed. DOI: 10.1016/j.matpr.2019.04.200.

28. M.M. Sarafraz, V. Nikkhah, M. Nakhjavani, A. Arya, Thermal performance of a heat sink microchannel working with biologically produced silver-water nanofluid: Experimental assessment, Exp. Therm. Fluid Sci. 91 (2018) 509-519.

29. R. Maheswaran, J. Sunil, Effect of nano sized garnet particles dispersion on the viscous behavior of extreme pressure lubricant oil, J. Mol. Liq. 223 (2016) 643–651.

30. R. Maheswaran, J. Sunil, Relative anti-wear property evaluation of nano garnet gear lubricant, Int. J. Surf. Sci. Eng. 11(4) (2017) 320–343.

31. R. Maheswaran, J. Sunil, R. Vettumperumal, K.K. Sadasivuni, Experimental investigation on the thermal properties of NiO-nanofluids, J. Mol. Liq. 8(7) (2019) 1577-1582.

32. J. Sunil, J. Vignesh, R. Vettumperumal, R. Maheswaran, R.A.A. Raja, The Thermal Properties of CaO-Nanofluids, Vacuum 161 (2019) 383-388.

33. A. Sajeeb, P.K. Rajendrakumar, Comparative evaluation of lubricant properties of biodegradable blend of coconut and mustard oil, J. Clean. Prod. 240 (2019) 118255.

34. G. Ajithkumar, N.H. Jayadas, M. Bhasi Analysis of the pour point of coconut oil as a lubricant base stock using differential scanning calorimetry, Lubr. Sci. 21(1) (2009) 13-26.

35. F. Aladedunye, R. Przybylski, Frying stability of high oleic sunflower oils as affected by composition of tocopherol isomers and linoleic acid content, Food Chem. 141(3) (2013)2373-2378.

36. R. Kreivaitis, J. Padgurskas, M. Gumbyte, V. Makareviciene, B. Spruogis, The influence of oxidation on tribological properties of rapeseed oil, Transport 26(2) (2011) 121-127.

37. L.I.F. Cabrera, E.A.G. Hernandez, J. Perez-Gonzalez, B.M.M. Santibanez, R. Lewis, Effects of jatropha lubricant thermooxidation on the tribological behaviour of engine cylinder liners as measured by a reciprocating friction test, Wear. 426-427 (2019b) 910-918.

38. S. Rani, M.L, Joy, K.P. Nair, Evaluation of physiochemical and tribological properties of rice bran oilebiodegradable and potential base stoke for industrial lubricants, Ind. Crops Prod. 65 (2015) 328-333.

39. A. Aravind, M.L. Joy, K.P. Nair, Lubricant properties of biodegradable rubber tree seed (Hevea brasiliensis Muell. Arg) oil, Ind. Crops Prod. 74 (2015) 14-19.

40. J.K. Mannekote, S.V. Kailas The effect of oxidation on the tribological performance of few vegetable oils, J. Mater. Res. Technol. 1(2) (2012) 91-95.

41. M.H. Mosarof, M.A. Kalam, H.H. Masjuki, A. Arslan, I.M. Monirul, A.M. Ruhul, Analysis of thermal stability and lubrication characteristics of Millettia pinnata oil, RSC Adv. 6(84) (2016) 81414-81425.

42. N.H. Jayadas, K.P. Nair, Study of the anti-wear properties of coconut oil using quantum chemical calculations and tribological tests, J. Tribol. 128 (2006) 654-659.

43. E.E.G. Rojas, J.S.R. Coimbra, J.T. Romero, Thermophysical Properties of Cotton, Canola, Sunflower and Soybean Oils as a Function of Temperature, Int. J. Food Prop.16(7) (2013) 1620-1629.

44. A, Sajeeb, P.K. Rajendrakumar, Comparative evaluation of lubricant properties of biodegradable blend of coconut and mustard oil, J. Clean. Prod. 240 (2019) 118255.

45. S.B. Naghadeh, S. Vahdatifar, Y. Mortazavi, A. Khodadadi, A. Abbasi, Functionalized MWCNTs effects on dramatic enhancement of MWCNTs/SnO2 nanocomposite gas sensing properties at low temperatures, Sensor. Actuat. B-Chem. 223 (2016) 252-260 .

46. A. Miranda, N. Barekar, B.J. McKay, MWCNTs and their use in Al-MMCs for ultra-high thermal conductivity applications: A review, J. Alloy. Compound. 774 (2019) 820-40.

47. N. Forintos, T. Czigany, Multifunctional application of carbon fiber reinforced polymer composites: Electrical properties of the reinforcing carbon fibers – A short review, Compos. B: Eng. 162 (2019) 331-343.

48. C. Zeng, C. Lin, J. Zhang, J. Liu, G. He, Y. Li, Yang Grafting hyperbranched polyester on the energetic crystals: Enhanced mechanical properties in highly-loaded polymer based composites, Compos. Sci. Technol. 184 (2019) 107842.

49. Y. Liad, Q, Wang, S. Wang, A review on enhancement of mechanical and tribological properties of polymer composites reinforced by carbon nanotubes and graphene sheet: Molecular dynamics simulations, Compos. Part B: Eng. 160 (2019) 348-361.

50. J. Meng, X. Li, C. Wang, H. Guo, J. Liu, H. Xu, Carbon nanotubes activate macrophages into a M1/M2 mixed status: recruiting naive macrophages and supporting angiogenesis, ACS Appl. Mat. Interfac. 7 (2015) 3180–3188.

51. K.K. Gangu, S. Maddilaa, S.B. Mukkamala, S.B. Jonnalagadda, Characteristics of MOF, MWCNT and graphene containing materials for hydrogen storage: A review, J. Energy Chem. 30 (2019) 132-144.

52. J. Huang, S. Her, X.X. Yang, M. Zhi, Synthesis and Characterization of Multi-Walled Carbon Nanotube/Graphene Nanoplatelet Hybrid Film for Flexible Strain Sensors, Nanomaterial. 8 (2018) 786.

53. A. Sengupta, N K. Gupta, MWCNTs based sorbents for nuclear waste management: A review, J. Environ. Chem. Eng. 5(5) (2017) 5099-5114.

54. J. Xiao, W. Li, Z. Sun, D.A. Lange, S.P. Shah, Properties of interfacial transition zones in recycled aggregate concrete tested by nanoindentation, Cement. Concrete Comp. 37 (2013) 276–292.

55. H. Huang, J. Yan, Possibility for rapid generation of high-pressure phases in single-crystal silicon by fast nanoindentation, Semicond. Sci. Technol. 30 (2015) 115001.

56. J. Chen, L. Tan, X. Yu, I. P. Etim, M. Ibrahim, K. Yang, Mechanical properties of magnesium alloys for medical application: A review, J. Mech. Behav. Biomed. 87 (2018) 68-79.

57. P. Khatri, S. Jain, S. Pandey, A cradle-to-gate assessment of environmental impacts for production of mustard oil using life cycle assessment approach, J. Clean. Prod. 166 (2017) 988-997.

58. M.A. Reddy, S. Ramaprabhu, Hydrogen adsorption properties of single-walled carbon nanotube-Nanocrystalline platinum composites, Int. J. Hydrog. Energy. 33 (2008) 1028-1034

59. P. Scherrer, Determination of the size and the internal structure of colloid particles by means of X-ray beams, News from the Society of Sciences, Gottingen, Math.-Phy. Cl 2 (1918) 98-100.