SURFACE MODIFICATION OF RUBBER FROM END-OF-LIFE TIRES FOR USE IN CONCRETE: A DESIGN OF EXPERIMENTS APPROACH

- rubber,

- tires,

- concrete,

- peroxide oxidation,

- Fenton

Copyright (c) 2020 SChQ

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.

Abstract

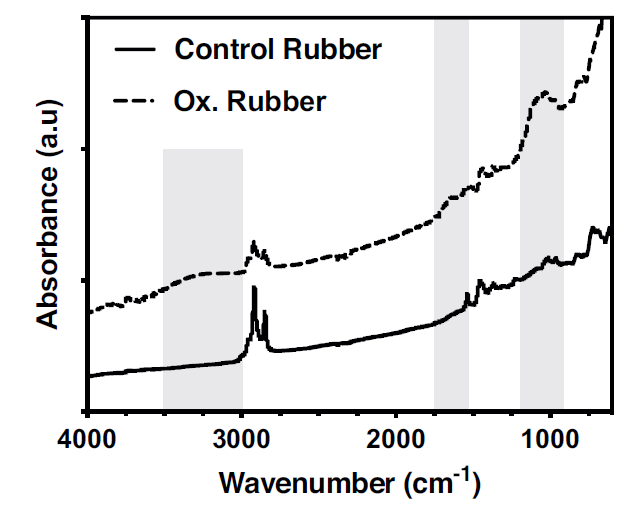

A large amount of discarded tire waste generated year after year has encouraged the scientific community to seek alternatives for recycling or reusing this waste. The cross-linked nature and the high number of additives in tires make recycling significantly difficult. Thus, the use of particulate rubber as filler for other materials such as concrete has emerged as an attractive alternative. However, the hydrophobic nature of the rubber and hydrophilic particles of cement decreases the compatibility at the cementitious matrix-rubber interface, affecting the concrete's final performance. This work presents a method based on hydrogen peroxide and Fenton for the oxidation of rubber particles from end-of-life tires to introduce hydrophilic groups on the surface of the particles to improve compatibility at the interface. The method was studied from an experimental design approach using a Rechtschaffner Resolution V design, PCA and PLSR in order to evaluate variables such as time, temperature and reactants. The concentration of H2O2 and reaction temperature was shown to increase the oxidation, while Fenton reduces the time of oxidation.

References

- J.B. van Beilen, Y. Poirier, Establishment of new crops for the production of natural rubber, Trends in Biotechnology. 25, 522-529, (2007)

- S. Rolere, S. Liengprayoon, L. Vaysse, J. Sainte-Beuve, F. Bonfils, Investigating natural rubber composition with Fourier Transform Infrared (FT-IR) spectroscopy: A rapid and non-destructive method to determine both protein and lipid contents simultaneously, Polymer Testing. 43, 83-93, (2015)

- Y. Qi, Z. Liu, S. Liu, L. Cui, Q. Dai, J. He, W. Dong, C. Bai, Synthesis of 1,3-butadiene and its 2-substituted monomers for synthetic rubbers, Catalysts. 9, (2019)

- D. Lopes, M.J. Ferreira, R. Russo, J.M. Dias, Natural and synthetic rubber/waste - Ethylene-Vinyl Acetate composites for sustainable application in the footwear industry, Journal of Cleaner Production. 92, 230-236, (2015)

- A.M. Rashad, A comprehensive overview about recycling rubber as fine aggregate replacement in traditional cementitious materials, International Journal of Sustainable Built Environment. 5, 46-82, (2016)

- A. Pehlken, E. Essadiqi, Scrap Tire Recycling in Canada, CANMET Materials Technology Laboratory, 2005.

- Y. Yildirim, Polymer modified asphalt binders, Construction and Building Materials. 21, 66-72, (2007)

- M. Nehdi, A. Khan, Cementitious Composites Containing Recycled Tire Rubber: An Overview of Engineering Properties and Potential Applications, Cement, Concrete and Aggregates. 23, 3-10, (2001)

- K.S. Son, I. Hajirasouliha, K. Pilakoutas, Strength and deformability of waste tyre rubber-filled reinforced concrete columns, Construction and Building Materials. 25, 218-226, (2011)

- X. Shu, B. Huang, Recycling of waste tire rubber in asphalt and portland cement concrete: An overview, Construction and Building Materials. 67, 217-224, (2014)

- M. Spizzuoco, A. Calabrese, G. Serino, Innovative low-cost recycled rubber–fiber reinforced isolator: Experimental tests and Finite Element Analyses, Engineering Structures. 76, 99-111, (2014)

- G. Pérez, A. Vila, L. Rincón, C. Solé, L.F. Cabeza, Use of rubber crumbs as drainage layer in green roofs as potential energy improvement material, Applied Energy. 97, 347-354, (2012)

- L. Solano, A.G. Ristvey, J.D. Lea-Cox, S.M. Cohan, Sequestering zinc from recycled crumb rubber in extensive green roof media, Ecological Engineering. 47, 284-290, (2012)

- J. Karger-Kocsis, L. Mészáros, T. Bárány, Ground tyre rubber (GTR) in thermoplastics, thermosets, and rubbers, Journal of Materials Science. 48, 1-38, (2013)

- P. Lima, S.P. Magalhães da Silva, J. Oliveira, V. Costa, Rheological properties of ground tyre rubber based thermoplastic elastomeric blends, Polymer Testing. 45, 58-67, (2015)

- S.B. Marinković, M. Malešev, I. Ignjatović, 11 - Life cycle assessment (LCA) of concrete made using recycled concrete or natural aggregates, in: F. Pacheco-Torgal, L.F. Cabeza, J. Labrincha, A. de Magalhães (Eds.), Eco-efficient Construction and Building Materials, Woodhead Publishing2014, pp. 239-266.

- R. Wang, P.M. Wang, X.G. Li, Physical and mechanical properties of styrene-butadiene rubber emulsion modified cement mortars, Cement and Concrete Research. 35, 900-906, (2005)

- A.O. Atahan, A.Ö. Yücel, Crumb rubber in concrete: Static and dynamic evaluation, Construction and Building Materials. 36, 617-622, (2012)

- F. Liu, G. Chen, L. Li, Y. Guo, Study of impact performance of rubber reinforced concrete, Construction and Building Materials. 36, 604-616, (2012)

- A. Richardson, K. Coventry, V. Edmondson, E. Dias, Crumb rubber used in concrete to provide freeze–thaw protection (optimal particle size), Journal of Cleaner Production. 112, 599-606, (2016)

- P. Sukontasukkul, Use of crumb rubber to improve thermal and sound properties of pre-cast concrete panel, Construction and Building Materials. 23, 1084-1092, (2009)

- S.E. Paje, J. Luong, V.F. Vázquez, M. Bueno, R. Miró, Road pavement rehabilitation using a binder with a high content of crumb rubber: Influence on noise reduction, Construction and Building Materials. 47, 789-798, (2013)

- H.M. Nor, J.R. Ebdon, Telechelic liquid natural rubber: A review, Progress in Polymer Science. 23, 143-177, (1998)