EXPERIMENTAL INVESTIGATION AND MECHANISM ANALYSIS: EFFECT OF CONCENTRATION AND TEMPERATURE ON THE VISCOSITY OF NOVEL MWCNT-MUSTARD OIL NANOFLUID

- Bio-lubricants; MWCNT; mustard oil; ultrasonication; dynamic viscosity; artificial neural network.

Copyright (c) 2020 SChQ

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.

Abstract

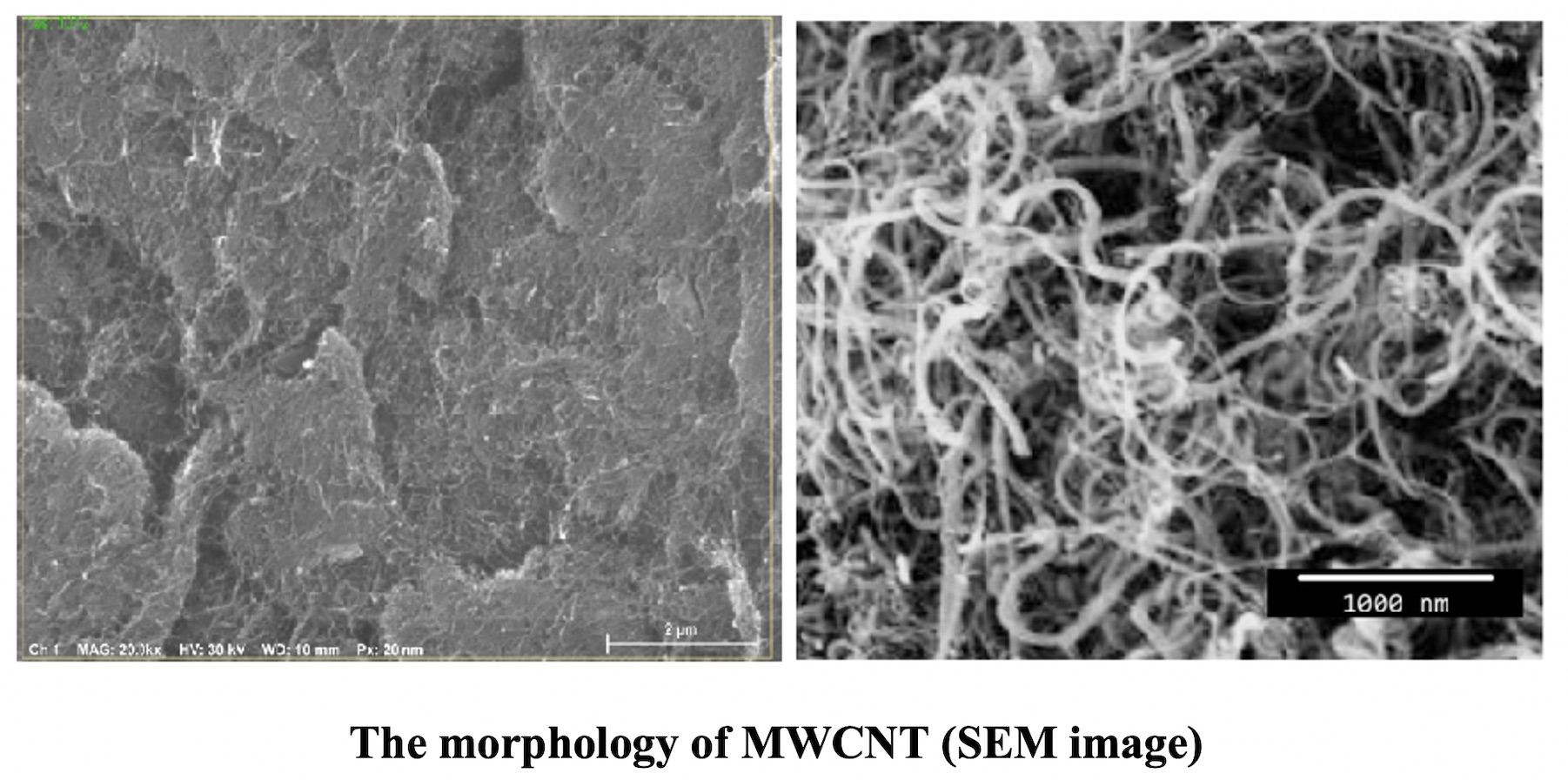

The bio-oils as alternative lubricating fluid is a potential solution for the automotive and industrial mechanical systems. The development of novel renewable and non-toxic bio-lubricants with better lubricating distinctiveness will strengthen the economy of farmers in the agricultural based countries. In the present study, different weight fractions of MWCNT-Mustard oil nanofluids are formulated and their possible effects on the dispersion stability and dynamic viscosity are experimentally investigated over the temperatures ranging from 40 to 100°C. It is observed that the dynamic viscosity and viscosity index of nanofluids were declined with temperature raise, while, it exponentially increased with the raise of MWCNT concentration. The maximum viscosity enhancement of 101.3% is achieved in comparison to the base fluid at 100ºC. Further, the dynamic viscosity of nanofluids is compared with different classical semi-empirical correlations, however, the remarkable conformities were observed from multilayer feed forward Perceptron (MLP) of artificial neural network (ANN).

References

- Y. Wang, C. Li, Y. Zhang, B. Li, M. Yang, X. Zhang, Comparative evaluation of the lubricating properties of vegetable-oil-based nanofluids between frictional test and grinding experiment, J. Manuf. Proc. 26 (2017) 94-104.

- E.E.G. Rojas, J.S.R. Coimbra, J.T. Romero, Thermophysical properties of cotton, canola, sunflower, and soybean oils as a function of temperature, Int. J. Food Prop. 16 (2013) 1620–1629.

- K.M. Kumar, A. Ghosh, Assessment of cooling-lubrication and wettability characteristics of nano-engineered sunflower oil as cutting fluid and its impact on SQCL grinding performance, J. Mater. Process. Tech. 237 (2016) 55-64.

- S.V. Sujith, A.K. Solanki, R.S. Mulik, Experimental evaluation on rheological behavior of Al2O3-pure coconut oil nanofluids, J. Mol. Liq. 286 (2019) 110905.

- M. Shahabuddin, H.H. Masjuki, M.A. Kalam, M.M.K. Bhuiya, H. Mehat, Comparative tribological investigation of bio-lubricant formulated from a nonedible oil source (Jatropha oil). Ind. Crops Prod. 47 (2013) 323-330.

- S. Rani, M.L, Joy, K.P. Nair, Evaluation of physiochemical and tribological properties of rice bran oilebiodegradable and potential base stoke for industrial lubricants, Ind. Crops Prod. 65 (2015) 328-333.

- S. Guo, C. Li, Y. Zhang, Y. Wang, B. Li, M. Yang, X. Zhang, G. Liu, Experimental evaluation of the lubrication performance of mixtures of castor oil with other vegetable oils in MQL grinding of nickel-based alloy, J. Clean. Prod. 140 (2017) 1060-1076.

- J.F. Hoffmann, J.F. Henry, G. Vaitilingom, R. Olives, M. Chirtoc, D. Caron, X. Py, Temperature dependence of thermal conductivity of vegetable oils for use in concentrated solar power plants, measured by 3omega hot wire method, Int. J. Therm. Sci. 107 (2016) 105-110.

- K.M. Arvind, V. Ajitanshu, Energy-exergy analysis of biodiesel fuels produced from waste cooking oil and mustard oil, Fuel 214 (2018) 386–408.

- A.R.M. Kumar, M. Kannan, G. Nataraj, A study on performance, emission and combustion characteristics of diesel engine powered by nano-emulsion of waste orange peel oil biodiesel, Renew. Energy 146 (2020) 1781-1795.

- R.D. Kulkarni, P.S. Deshpande, S.U. Mahajan, P.P. Mahulikar, Epoxidation of mustard oil and ring opening with 2-ethylhexanol for biolubricants with enhanced thermo-oxidative and cold flow characteristics, Ind. Crops Prod. 49 (2013) 586– 592.

- M.H Esfe, M. Bahiraei, A. Mir, Application of conventional and hybrid nanofluids in different machining processes: A critical review, Adv. Colloid. Interface Sci., https://doi.org/10.1016/j.cis.2020.102199.

- S. Ayamannil, K.R. Perikinalil, Comparative evaluation of lubricant properties of biodegradable blend of coconut and mustard oil, J. Clean. Prod. 240 (2019) 118255.

- S. Mia, N. Ohno, Prospect of mustard and coconut oil as environment friendly lubricant for Bangladesh. In: Proc. Of International Conference on Environmental Aspects of Bangladesh ICEAB10) (2010, Japan).

- K. Poonam, J. Suresh, P. Suneel, A cradle-to-gate assessment of environmental impacts for production of mustard oil using life cycle assessment approach, J. Clean. Prod.166 (2017) 988-997.

- F. Aladedunye, R. Przybylski, Frying stability of high oleic sunflower oils as affected by composition of tocopherol isomers and linoleic acid content, Food Chem. 141(3) (2013) 2373-2378.

- R. Kreivaitis, J. Padgurskas, M. Gumbyte, V. Makareviciene, B. Spruogis, The influence of oxidation on tribological properties of rapeseed oil, Transport 26(2) (2011) 121-127.

- S.B. Naghadeh, S. Vahdatifar, Y. Mortazavi, A. Khodadadi, A. Abbasi, Functionalized MWCNTs effects on dramatic enhancement of MWCNTs/SnO2 nanocomposite gas sensing properties at low temperatures, Sensor. Actuat. B-Chem. 223 (2016) 252-260 .

- A. Miranda, N. Barekar, B.J. McKay, MWCNTs and their use in Al-MMCs for ultra-high thermal conductivity applications: A review, J. Alloy. Compound. 774 (2019) 820-40.

- N. Forintos, T. Czigany, Multifunctional application of carbon fiber reinforced polymer composites: Electrical properties of the reinforcing carbon fibers – A short review, Compos. B: Eng. 162 (2019) 331-343.

- C. Zeng, C. Lin, J. Zhang, J. Liu, G. He, Y. Li, Yang Grafting hyperbranched polyester on the energetic crystals: Enhanced mechanical properties in highly-loaded polymer based composites, Compos. Sci. Technol. 184 (2019) 107842.

- Y. Liad, Q. Wang, S. Wang, A review on enhancement of mechanical and tribological properties of polymer composites reinforced by carbon nanotubes and graphene sheet: Molecular dynamics simulations, Compos. Part B: Eng. 160 (2019) 348-361.

- J. Meng, X. Li, C. Wang, H. Guo, J. Liu, H. Xu, Carbon nanotubes activate macrophages into a M1/M2 mixed status: recruiting naive macrophages and supporting angiogenesis, ACS Appl. Mat. Interfac. 7 (2015) 3180–3188.

- K.K. Gangu, S. Maddilaa, S.B. Mukkamala, S.B. Jonnalagadda, Characteristics of MOF, MWCNT and graphene containing materials for hydrogen storage: A review, J. Energy Chem. 30 (2019) 132-144.

- J. Huang, S. Her, X.X. Yang, M. Zhi, Synthesis and Characterization of Multi-Walled Carbon Nanotube/Graphene Nanoplatelet Hybrid Film for Flexible Strain Sensors, Nanomaterial. 8 (2018) 786.

- A. Sengupta, N.K. Gupta, MWCNTs based sorbents for nuclear waste management: A review, J. Environ. Chem. Eng. 5(5) (2017) 5099-5114.

- G. Teng, L. Changhe, Z. Yanbin, Y. Min, J. Dongzhou, J. Tan, H. Yali, L. Runze, Dispersing mechanism and tribological performance of vegetable oil-based CNT nanofluids with different surfactants, Tribol. Int. 131 (2019) 51-63.

- A.N. Omrani, E. Esmaeilzadeh, M. Jafari, A. Behzadmehr, Effects of multi walled carbon nanotubes shape and size on thermal conductivity and viscosity of nanofluids, Diam. Relat. Mater. 93 (2019) 96-104.

- A. Einstein, Eine neue bestimmung der moleküldimensionen, Ann. Phys. 324 (1906) 289–306.

- I.M. Krieger, T.J. Dougherty, A mechanism for non-Newtonian flow in suspensions of rigid spheres, Trans. Soc. Rheol. 3 (1959) 137–152.

- H. Brinkman, The viscosity of concentrated suspensions and solutions, J. Chem. Phys. 20 (1952) 571-571.

- L.E. Nielsen, Generalized equation for the elastic moduli of composite materials, J. Appl. Phys. 41(1970) 4626‐4627.

- Batchelor, The effect of Brownian motion on the bulk stress in a suspension of spherical particles, J. Fluid Mech. 83 (1977) 97–117.

- W.J. Tseng, K.C. Lin, Rheology and colloidal structure of aqueous TiO2 nanoparticle suspensions, Mater. Sci. Eng. A. 355(1-2) (2003) 186-192.

- S.E.B. Maiga, C.T. Nguyen, N. Galanis, G. Roy, Heat transfer behaviours of nanofluids in a uniformly heated tube, Superlattice. Microst. 35 (2004) 543–557.

- H. Chen, Y. Ding, C. Tan, Rheological behaviour of nanofluids, New J. Phys. 9 (2007) 367.

- C.T. Nguyen, F. Desgranges, N. Galanis, Viscosity data for Al2O3–water nanofluid—hysteresis:is heat transfer enhancement using nanofluids reliable, Int. J. Therm. Sci. 2 (2008) 103‐111.

- B. Abedian, M. Kachanov, On the effective viscosity of suspensions, Int. J. Eng. Sci. 48 (2010) 962–965.

- Harandi, S. Sarbolookzadeh, A. Karimipour, M. Afrand, M. Akbari, An experimental study on thermal conductivity of FZ MWCNTs–Fe3O4/EG hybrid nanofluid: effects of temperature and concentration, Int. Commun. Heat and Mass Tran. 76 (2016) 171–177.

- L. Sundar, G.O. Syam, E.V.R. Irurueta, M.K. Singh, A.C.M. Sousa, Thermal conductivity and viscosity of hybrid nanfluids prepared with magnetic nanodiamondcobalt oxide (ND-Co3O4) nanocomposite, Case Stud. Therm. Eng. 7 (2016) 66–77.

- M. Akbari, M. Afrand, A. Arshi, A. Karimipour, An experimental study on rheological behavior of ethylene glycol based nanofluid: proposing a new correlation as a function of silica concentration and temperature, J Mol Liq. 233 (2017) 352‐357.

- A.A.A. Alrashed, A. Karimipour, S.A. Bagherzadeh, M.R. Safaei, M. Afrand, Electro‐ and thermophysical properties of water‐based nanofluids containing copper ferrite nanoparticles coated with silica: experimental data, modeling through enhanced ANN and curve fitting. Int. J. Heat Mass Trans. 127 (2018) 925‐935.

- A. Asadi, M. Asadi, A. Rezaniakolaei, L.A. Rosendahl, S. Wongwises, An experimental and theoretical investigation on heat transfer capability of Mg (OH) 2/MWCNT-engine oil hybrid nano-lubricant adopted as a coolant and lubricant fluid, Appl. Therm. Eng. 129 (2018) 577–586.

- S. Ghasemi, A. Karimipour, Experimental investigation of the effects of temperature and mass fraction on the dynamic viscosity of CuO‐paraffin nanofluid. Appl. Therm. Eng. 138 (2018) 189‐197.

- A. Karimipour S.A. Bagherzadeh M. Goodarzi, Synthesized CuFe2O4/SiO2 nanocomposites added to water/EG: evaluation of the thermophysical properties beside sensitivity analysis & EANN, Int. J .Heat Mass Trans. 127 (2018) 1169‐1179.