A REVIEW OF ABACA FIBER-REINFORCED POLYMER COMPOSITES: DIFFERENT MODES OF PREPARATION AND THEIR APPLICATIONS

- polymer composites,

- abaca,

- fiber reinforcement,

- surface modification

Copyright (c) 2020 SChQ

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.

Abstract

Fiber-reinforced polymer composites have received increased attention due to their environmental friendliness and sustainability, aside from at par - if not better - property enhancement achieved through fiber reinforcement over mineral-based fillers. The purpose of this article is to provide a comprehensive review on the various methods of fiber-based polymer composites preparation as well as their applications, particularly focusing on abaca-reinforced hybrid materials. Among the natural fibers available in the market, abaca fiber has been a major contender in the development of natural fiber composites. It has a great potential to be a renewable fiber source for industrial and technological applications owing to its inherent high mechanical strength, durability, flexibility and long fiber length. Impacts of different treatment strategies of abaca-based composites preparation resulting in property enhancements over bare polymer counterparts and that of synthetic fibers are discussed. Being eco-friendly and naturally sustainable, abaca fiber-reinforced composites can also exhibit better strength without substantial weight gain – characteristics that have been exploited in various commercial and technological uses. How these enhanced properties of the resulting composites had led in a wide range of applications such as in the automobile and construction industries and other fields had been included as well.

References

- D.P. Penaloza, Philipp. J. Sci., 148, 827 (2019).

- D. P. Penaloza, D.J. Sandberg, M.V. Giotto, T.A.P. Seery, Polym. Eng. Sci., 55, 2349 (2015).

- A. Okada, A. Usuki, A, Macromol. Mater. Eng., 291, 1449 (2006).

- E.P. Giannelis, Appl. Organomet. Chem., 12, 675 (1998).

- K. Hill, B. Swiecki, J. Cregger, Center for Automotive (2012), https://www.cargroup.org/wp-content/uploads/2017/02/The-Bio_Based-Materials-Automotive-Value-Chain.pdf

- G. Se‘be, N.S. Cetin, C.A.S. Hill, M. Hughes, Appl Compos. Mater., 7, 341 (2000).

- S.V. Joshi, L.T. Drzal, A.K. Mohanty, S. Arora, Compos. Part A Appl. Sci. Manuf., 35, 371 (2004).

- O. Güven, S.N. Monteiro, E.A.B. Moura, J.W. Drelich, Polym. Rev., 56, 702 (2016).

- T. Johnson, History of composites (2018), https://www.thoughtco.com/history-of-composites-820404

- F. Ahmad, H.S. Choi, M.K. Park, Macromol. Mater. Eng., 300, 10 (2015).

- J. Holbery, D. Houston, JOM, 58, 80 (2006).

- L. Mohammed, M.N.M. Ansari, G. Pua, M. Jawaid, M.S. Islam, Int. J. Polym., 2015, 1 (2015).

- A. Wagenführ, Lightweight Design worldwide, 10, 3 (2017).

- J. Njuguna, P. Wambua, K. Pielichowski and K. Kayvantash, In Cellulose fibers: bio-and nano-polymer composites, edited by S. Kalia, B.S. Kaith, I. Kaur, Springer Nature, pp. 661-700 (2011), https://link.springer.com/chapter/10.1007/978-3-642-17370-7_23

- L.J. Bingham, Automotive Industries 180, 83 (2000).

- F.A. Mirza, A.M. Afsar, B.S. Kim, J.I. Song, Composites Research, 22, 41 (2009).

- A.G. Daimler, New Mercedes-Benz A-class: Environmental Certificate for the A-class (2018), https://media.daimler.com/marsMediaSite/en/instance/ko/New-Mercedes-Benz-A-Class-Environmental-Certificate-for-the-A-Class.xhtml?oid=40866452

- R. Fangueiro and S. Rana, Green composites for advanced technical applications. In 5th International Conference on Innovative Natural Fibre Composites for Industrial Applications. Rome, Italy (2015), https://www.researchgate.net/publication/285578124_Green_Composites_for_Advanced_Technical_Applications

- M. Ho, H. Wang, J.H. Lee, C. Ho, K. Lau, J. Leng, D. Hui, Compos. Part B-Eng., 43, 3549 (2012).

- H. Venkatasubramanian, C. Chaithanyan, S. Raghuraman, and T. Panneerselvam, Int. J. of Adv. Res. in Sci. Eng. Tech., 1, 40 (2014).

- G. Suresh, L.S. Jayakumari, G. Suresh, L.S.Jayakumari, Polímeros, 25, 49 (2015).

- V. Tserki, N.E. Zafeiropoulos, F. Simon, and C. Panayiotou, Compos. Part A Appl. Sci. Manuf., 36, 1110 (2005).

- A. Célino, S. Fréour, F. Jacquemin, P. Casari, Front. Chem., 1, 43 (2013).

- S. Ochi, Compos. Part A Appl. Sci. Manuf., 37, 1879 (2006).

- K. Vijayalakshmi, C.Y.K. Neeraja, A. Kavitha, J. Hayavadana, Transactions on Engineering and Sciences, 2, 16 (2014).

- R.B. Armecin, F.G. Sinon and L.O. Moreno, In Biomass and Bioenergy, edited by K.R.Hakeem, M. Jawaid and U. Rashid, Springer Nature, pp. 108-116 (2014), https://www.springer.com/gp/book/9783319075778

- R. Punyamurthy, D. Sampathkumar, B. Bennehalli, C.V. Srinivasa, Chem. Sci. Trans., 2, 413 (2013).

- PhilFIDA, Final technical report: Improvement of fiber extraction and identification of higher yielding varieties. Manila. (2009), http://www.philfida.da.gov.ph/images/Publications/abacasustainabilitymanual/ASM.pdf

- R. Sun, J.M. Fang, A. Goodwin, J.M. Lawther, and A.J. Bolton, J. Agric. Food Chem., 46, 2817 (1998).

- K. Liu, H. Takagi, Z. Yang, Compos. Part A Appl. Sci. Manuf., 45, 14 (2013).

- B. Madsen, E.K. Gamstedt, Adv. Mater. Sci. Eng., 2013, 564346 (2013).

- M.A. Paglicawan, B.A. Basilia, B.S. Kim, Composites Research, 26, 165 (2013).

- F. Göltenboth, W. Mühlbauer, Abacá - cultivation, extraction and processing. In Industrial Applications of Natural Fibres (pp. 163–179). Chichester, UK: John Wiley & Sons, Ltd. https://doi.org/10.1002/9780470660324.ch7

- A.K. Bledzki, A.A. Mamun, M. Lucka-Gabor, V.S. Gutowski, Express Polym. Lett., 2, 413 (2008).

- L.O. Moreno, Philipp. J. Crop Sci., 26, 21 (2001).

- B.C. Tobias, Tomorrow’s Materials: Today, 34, 211 (1989).

- B.C. Tobias, In International SAMPE Symposium and Exhibition, 35 th, Anaheim, CA, pp. 970–978 (1990)

- M. Shibata, K. Takachiyo, K. Ozawa, R. Yosomiya, H. Takeishi, J. Appl. Polym., 85, 129 (2002).

- M. Shibata, R. Yosomiya, N. Ohta, A. Sakamoto, H. Takeishi, Polym. Polym. Compos., 11, 359 (2003).

- DaimlerChrysler. Annual Report. Stuttgart, Germany (2004), https://www.daimler.com/documents/investors/berichte/geschaeftsberichte/daimlerchrysler/daimler-ir-annualreport-2004.pdf

- A.K. Bledzki, P. Franciszczak, Z. Osman, M. Elbadawi, Indus. Crop. Prod., 70, 91 (2015).

- R. Greiner, T. Schloeser, Rovings comprising Musaceae or banana plant fibers, used to reinforce composite automobile components, have limited contamination by processing aids, DE10349110B3 (2004). https://patents.google.com/patent/DE10349110B3/en

- A.K. Bledzki, A. Mamun, O. Faruk, Express Polym. Lett., 1, 755 (2007).

- J. Gironès, J.P. Lopez, F. Vilaseca, P.J. Herrera-Franco, P. Mutje, Compos. Sci. Technol., 71, 122 (2011).

- M.R. Rahman, M.M. Huque, M.N. Islam, M. Hasan, Compos. Part A Appl. Sci. Manuf., 40, 511( 2009).

- A.K. Bledzki, A.A. Mamun, A. Jaszkiewicz, K. Erdmann, Compos. Sci. Technol., 70, 854 (2010).

- M. Cai, H. Takagi, A.N. Nakagaito, Y. Li, G.I.N. Waterhouse, Compos. Part A Appl. Sci. Manuf., 90, 589 (2016).

- T. Tumolva, M. Kubouchi, S. Aoki, T. Sakai, In Proceedings of the 18th International Conference on Composites Materials, pp. 21–26 (2011). https://pdfs.semanticscholar.org/bc92/6868e47edd8f121bdfca500b737ee11a0ac2.pdf

- R.R. Niranjan, S. Junaid Kokan, R. Sathya Narayanan, S. Rajesh, V.M. Manickavasagam, B.V. Ramnath, Adv. Mater. Res., 718-720, 63 (2013).

- A.S. Suvarna, A. Katagi, J. Pasanna, S. Kumar, P.V. Badyankal, S.K. Vasudeva, Mat. Sci. Res. India, 12, 54 (2015).

- A.K. Bledzki, A. Jaszkiewicz, Compos. Sci. Technol., 70, 1687 (2010).

- E.H. Agung, S.M. Sapuan, M.M. Hamdan, H. Zaman, U. Mustofa, Int. J. Phys. Sci., 6, 2100 (2011).

- M.A. Paglicawan, B.S. Kim, B.A. Basilia, C.S. Emolaga, D.D. Marasigan, P.E.C. Maglalang, Int. J. of Precis. Eng. and Manuf.-Green Tech., 1, 241 (2014).

- B.V. Ramnath, S.J. Kokan, R.N. Raja, R. Sathyanarayanan, C. Elanchezhian, A.R. Prasad, V.M. Manickavasagam, Mater. Des., 51, 357 (2013).

- T.A. Dankovich, Y.L. Hsieh, Cellulose, 14, 469 (2007).

- X. Li, L.G. Tabil, S. Panigrahi, J. Polym. Environ., 15, 25 (2007).

- V.S.D. Mesias, A.B.S. Agu, P.J.L. Benablo, C.H. Chen, D.P. Penaloza, J. Ecol. Eng., 20, 1 (2019).

- B.S.C. Siy, J.A.X.C. Tan, K.P. Viron, N.J.B. Sajor, G.N.C. Santos and D.P. Penaloza, Cellulose Chem. Technol., 54, 365 (2020).

- S. Haig Zeronian, H. Kawabata, K.W. Alger, Text. Res. J., 60, 179 (1990).

- M.A. Semsarzadeh, Polym. Compos., 7, 23 (1986).

- P.K. Ray, A.C. Chakravarty, S.B. Bandyopadhaya, J. Appl. Polym. Sci., 20, 1765 (1976).

- J.Y.Y. Heng, D.F. Pearse, F. Thielmann, T. Lampke and A. Bismarck, Compos. Interfaces, 14, 581 (2007).

- M.N. Belgacem, P. Bataille, S. Sapieha, J. Appl. Polym. Sci., 53(4), 379 (1994).

- I. Sakata, M. Morita, N. Tsuruta, K. Morita, J. Appl. Polym. Sci., 49, 1251 (1993).

- M. Ragoubi, D. Bienaimé, S. Molina, B. George, A. Merlin, Ind Crop Prod, 31, 344 (2010).

- Q. Wang, A. Ait-Kadi, S. Kaliaguine, J. Appl. Polym. Sci., 45, 1023 (1992).

- J. Gassan, V.S. Gutowski, Compos. Sci. Technol., 60, 2857 (2000).

- D.P. Penaloza, T.A.P. Seery, Mater. Res., 22, e201800192 (2019).

- S.C.O. Ugbolue, Text. Prog., 20, 1 (1990).

- M.M. Kabir, H. Wang, K.T. Lau, F. Cardona, Compos. Part B-Eng., 43, 2883 (2012).

- Y. Xu, S. Kawata, K. Hosoi, T. Kawai, S. Kuroda, S. Express Polym. Lett., 3, 657 (2009).

- S. Mishra, J.B. Naik, Y.P. Patil, Compos. Sci. Technol., 60, 1729 (2000).

- S. Kalia, B.S. Kaith, I. Kaur, Polym. Eng. Sci., 49, 1253 (2009).

- A. Hebeish, T. J. Guthrie, The chemistry and technology of cellulosic copolymers, Springer-Verlag Berlin Heidelberg (2012), https://www.springer.com/gp/book/9783540101642

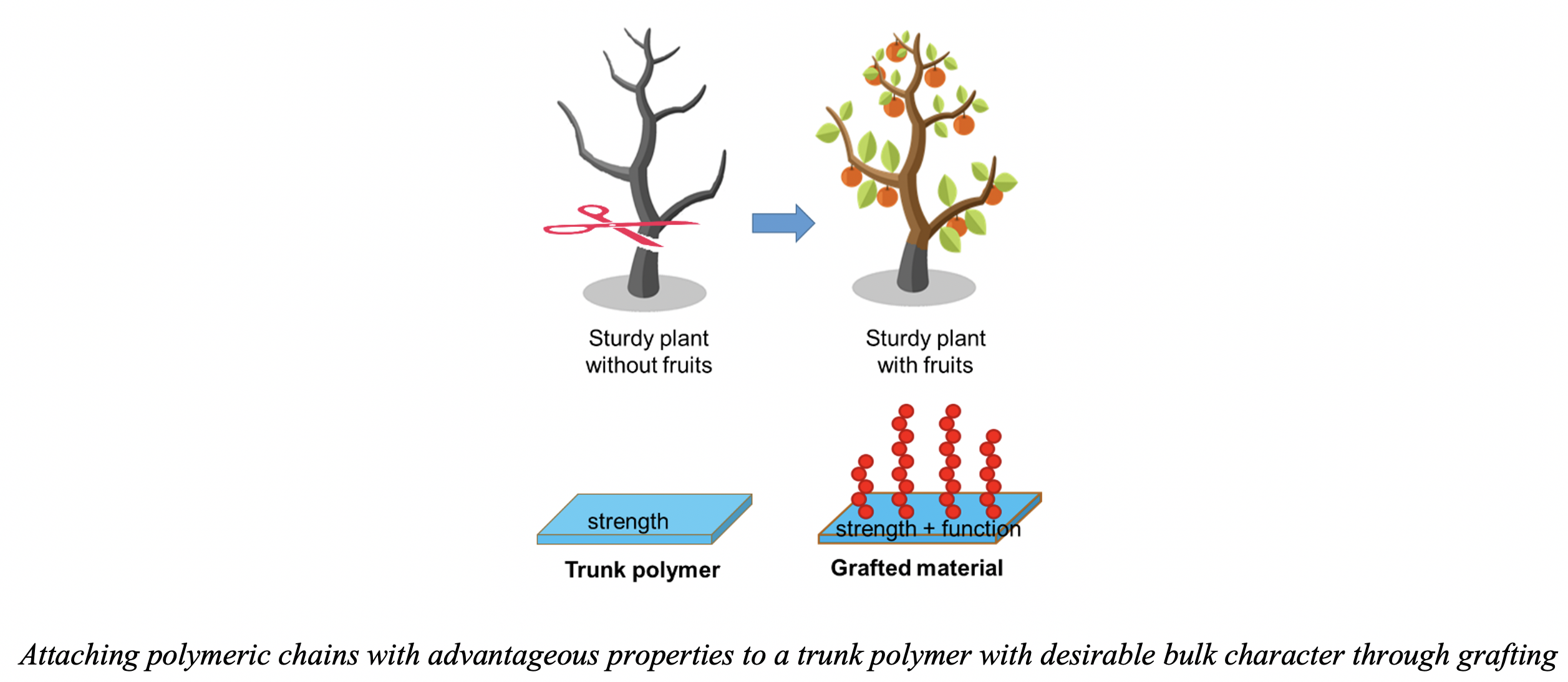

- D. Roy, M. Semsarilar, J.T. Guthrie, S. Perrier, Chem. Soc. Rev., 38, 2046 (2009).

- V.H. Pino-Ramos, A. Ramos-Ballesteros, F. López-Saucedo, J.E. López-Barriguete, G.H.C. Varca, E. Bucio, Top. Curr. Chem. (Z) 374, 63 (2016).

- Y. Bhardwaj, M. Tamada, Y.C. Nho, M. Nasef, O. Guven, IAEA: Vienna, (2014), http://www-naweb.iaea.org/napc/iachem/working_materials/Graftingprotocol.pdf

- M.M. Hassan, M.H. Wagner, Rev. Adhes. Adhes., 4, 1 (2016).

- A. Rudin, P. Choi, A. Rudin, P. Choi, The Elements of Polymer Science & Engineering, 341 (2013).

- N.H. Mohamed, M. Tamada, Y. Ueki, N. Seko. Radiat. Phys. Chem., 82, 63 (2013).

- J. Sharif, S.F. Mohamad, N.A.F. Othman, N.A. Bakaruddin, H.N. Osman, O. Güven, Radiat. Phys. Chem., 91, 125 (2013).

- J.F. Madrid, G.M. Nuesca, L.V. Abad, Radiat. Phys. Chem., 85, 182 (2013).

- F. Khan, Macromol. Biosci., 5, 78 (2005).

- A.K. Mohanty, S. Patnaik, B.C. Singh, M. Misra, J. Appl. Polym. Sci., 37, 1171 (1989).

- V.K. Thakur, A.S. Singha, B.N. Misra, J. Appl. Polym. Sci.,122, 532 (2011).

- A.M. El-Naggar, M.B. El-Hosamy, A.H. Zahran, M.H. Zondy, Am. Dyestuff Rep, 81, 40 (1992).

- J.F. Madrid, Y. Ueki, N. Seko, Radiat. Phys. Chem., 90, 104 (2013).

- J.F. Madrid, P.J.E. Cabalar, L.V.Abad, J. Nat. Fibers, 15, 625 (2018).

- W. Machnowski, B. Gutarowska, J. Perkowski, H. Wrzosek. Text. Res. J., 83, 44 (2013).