- Biomaterials,

- biocompatible,

- chitosan,

- polylactic acid,

- bone regeneration.

Copyright (c) 2019 Journal of the Chilean Chemical Society

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.

Abstract

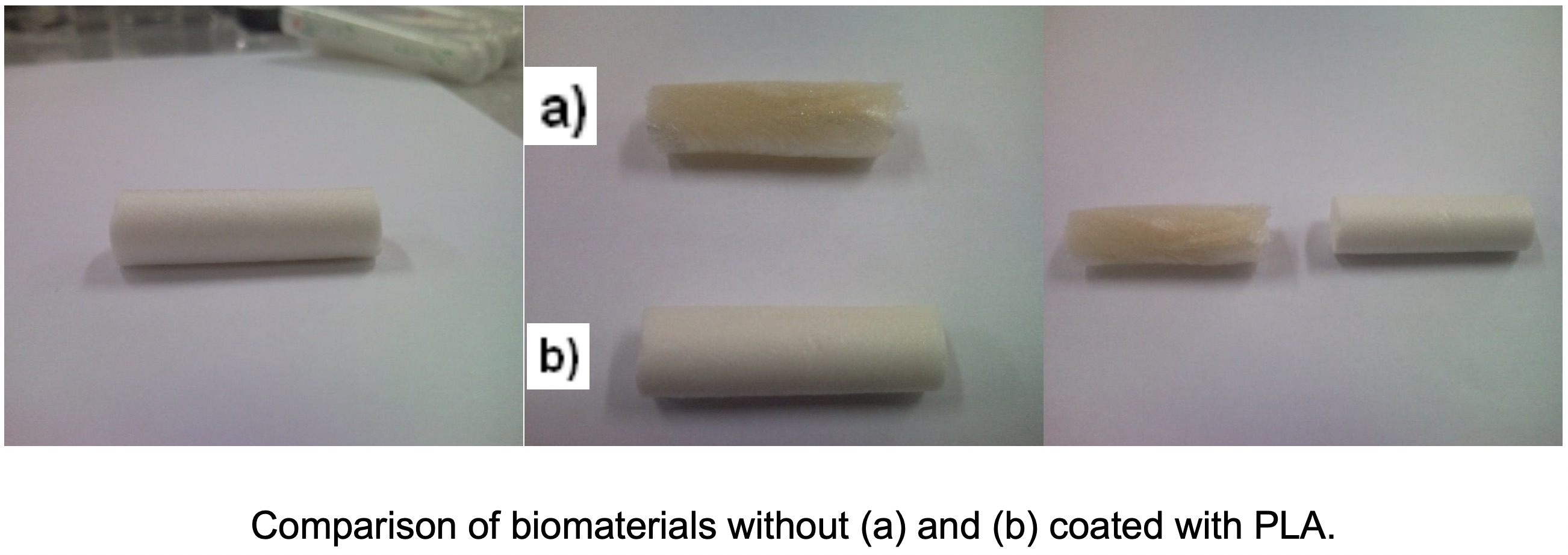

The need to find new therapies to improve the functioning of the injured tissue has made emerge a multidisciplinary field of research. Field that is related to the problems that exist for transplant to a patient with defect in their tissues and nerves, these trasplants are one of the most serious and costly health problems. In biomaterials research has undergone a major expansion, generating a variety of stands of different chemical nature. Biocompatible materials for human where they serve the same function as the actual tissues and also exhibit a total degradation in the body without the need for any other post-operation to remove a device installed on the bone region. Biodegradables and biocompatible composites prepared were subjected to studies to test the best concentrations of components of these, for example Chitosan(CH), hydroxyapatite(HAP) and polylactic acid(PLA), with these is created a material that fulfills the requirements for a good result in bone regeneration. The results showdifferent analyses of the composites that the proportion of Chitosan 4%, hydroxyapatite 3% and polylactic acid 1.5% is the more appropriate composition to produce a bone regeneration.

References

- Cárdenas G., Anaya P., von Plessing C., Rojas C. and Sepúlveda J. J. Mater. Sci.: Mater. Med. 19, 2397 (2008).

- Mi F., Wu Y., Shyu S., Schoung J., Huang Y., Tsai Y, Hao J. J. Biomed. Mater. Res. 59, 438 (2002).

- Muzzarelli R. “Chitin”.Pergamon Press Editorial. First edition, pag. 2 (1974).

- CASTRO, P. Propiedades de la quitina y el quitosan. Periodismo de Ciencia y Tecnología. México. (2000).

- Bernabéu Martínez, E.; López-Oliva Muñoz,;Larena Pellejero, A, Tur Gil, A.; de la Piedra Gordo, Mª. C.; Montero Escobar, M.; Estudio de la composición ósea para su apropiada regeneración con materiales implantados.

- Langer R. and Vacanti J. P. Tissue engineering. Science. 260, 920, (1993).

- Catalina Estrada; Ana Cristina Paz.: Luis Ernesto Lopez,; Ingeniería de Tejido Óseo: Consideraciones Basicas,; Revista EIA, ISSN 1974-1273. Numero 5 p. 93-100. (2006).

- Kneser U, Shaefer DJ, Polykandriotis E, Horch RE. Tissue engineering of bone: The reconstructive surgeons point of view. J Cell Mol Med.10 (1), 7, (2006).

- Mauthews JL. Bone structure and ultrastructure. Fundamental and clinical bone physiology. Lippincon. 44, (1980).

- Yoshikawa H. Myui A. Bone Tissue engineering with porous hydroxiapatite ceramics. J. Artif. Organs. 8(3):131, (2005).

- Damien C, Parsons R. Bone graft and bone graft substitutes: a review of current technology and applications. J. of Applied Biomaterials. 2,187, (1991).

- Pavlov MP, Mano JF, NevesNM, Reis RL, Fibers and 3D scaffolds from biodegradable stach-based blends: production and characterization. Macromol. Biosci. 4, 776, (2004).

- Parikh SN. Bone graft substitutes in modem orthopedics, Orthopedics. 25, 1301, (2002).

- Lahiji A, Sohrabi A, Hungerford DS, Frondoza CG, Chitosan supports the expression of extracellular matrix proteins in human osteoblast and chondrocytes. J. Biomed. Maters. Res. 51, 586, (2000).

- Li Z, Ramay HR, Hauch KD, Xiao D, Zhang M, Chitosan-alginate Hybrid scaffold for bone tissue engineering. Biomaterials. 26, 3919, (2005).

- Day RM, Boccaccini AR, Maquet V, Shurey S, Forbes A, Gabe SM, Jerome R. In vivoCharacterisation of a novel bioresorbable poly( lactide-co-glycolide) tubular foam scaffold for tissue engineering application. J. Mater. Sci. Mater. Med. 15, 729, (2004).

- Wu Y-Chun, Shaw S-Yu, Lin H-Ru, Lee T-Min, Yang C-Yu. Bone tissue engineering evaluation based on rat calvaria stromal cell cultured on modified PLGA scaffolds. Biomaterials. 27, 896, (2006).

- Wang HT, Palmer H, Linhardt RJ, Glanagan DR, Echmitt E. Degradation of poly (ester) microspheres. Biomaterials.11,679, (1990).

- Whateley TL. 1993. Biodegradable microspheres for controlled delivery, in: Whaterley TL, ed. Encapsulation and controlled release, ReinoUnido: Harwood Acad, pp:57.

- Linhardt RJ, Flanagan DR, Schmitt E, Wang HT. Quantitative analysis of the monomer product formed on the hydrolysis of poly (ester) and poly (anhidrides). PolymPrepr. 30, 464, (1989).

- Bodmeier R, McGinity JW. 1987.The preparation and evaluation of drug-containing poly (DL-lactide) microspheres formed by the solvent evaporation. Pharm. Res.4, 465, (1987).

- Spenlehauer GM, Vert M, Benoit JP, Chabot F, Veillard M. Biodegradable cisplatin microspheres prepared by the solvent evaporation method: Morphology and release characteristics. J. Contr. Rel. 7, 217, (2006).